The brand

1904

Constant BILLON created in Villeurbanne (69) his own workshop specialized in knitted mesh and veils.

1920

The company carries out a conversion into knitted fabrics for the woman’s ready-to-wear field as well as swimwear garment makers and woman’s lingerie specialists. All these sectors will meet a significant expansion.

1950-1960

Birth of artificial and synthetic fibers. Prompt to foresee all the benefits they could get out of these new fibers, Billon resolutely turns towards the knitting of these new materials to become in 1960 one of the first knitters to offer knitted fabrics integrating Lycra. The Billon group will pace their development based on technical know-how learnings in the knitting sector.

1960-1980

Creation of the Tricotages de Lyon company in Villeurbanne (69), in 1962.

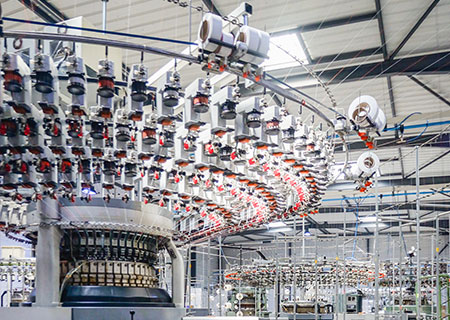

This company is specialized in large diameter circular knitting machines.

The Tricotages de Jujurieux company is then created in 1968, with a totally new approach when it comes to knitted fabrics, based on the use of flat knitting machines and jacquard rachel knitting machines. These new technics allowed the development of knitted curtains and laces. The necessity to entirely control the quality of their fabrics and to improve the delivery times leads the Billon group to acquire in 1978 Alberti Teintures in Saint Vulbas (01), specialized in fabrics’ dyeing, finishing and sizing. Billon secures with this latest acquisition the complete integration of their production.

1990-2000

With the will to innovate and to get a better position on a dynamic market – the technical fabrics – led the Billon group to develop in 1990 a department in this field of activity : Billon Technic was born, specialized in fabrics dedicated to professional and industrial applications.

1994

The creation of technical farbics has then been reinforced by the Rachel Créations takeover, in order to ensure part of Billon Technic fabrics, which will be later on transferred to Jujurieux (01).

1998

Billon Frères has been listed on the Second Market of the Paris Bourse by the founder’s great sons.

2004

The company finds its independance back and Billon Frères becomes Billon Créa’Lys in 2006.

2008

The new management takes the decision to transfer the whole activity, as well as the headquarters in the Plaine de l’Ain industrial pole (01), next to Alberti Teintures.

2013

D2P box, a company specialized in ready-to-wear fabrics, takes over Billon, its circular knitting and deying units, and becomes D2P Billon.

2019

D2P Billon wins the creator of the year award at the Interfilière fair in Paris, for its swimwear collection’s great creativity and high quality of its fabrics.

2020

D2P Billon has been bought by an investor keen on local industrial fabrics. D2P Billon becomes Billon 1904 with 2 departments : Billon Design and Billon Technic.

Our every day commitments to answer your needs

Creativity

Each new season is the occasion for our team to run wild.

Where do they get their inspiration from ? Directly by keeping up with the trends, but also from a century’s worth of archives, patterns, colors, textures and crushes in order to conceive fabrics that will entice the customers and correspond to the future leading products.

Each new collection is the result of countless researches hours and hard work, it is no coincidence but the reflexion of exclusive selections to create tomorrow’s fashion.

Each need being also unique, the team offers to build up personalized, taylor-made products, to stick to the customers’ DNA.

Vertical integration

The vertical integration of our tool is one of Billon’s major strengths.

From the fabrics’ creation, from the knitting to the finishing process, all the stages are done in our units and ensure the know-how, the quality of our products, their uniqueness as well as a local production in the Ain department ( 01 – FRANCE)

Reactivity

This is Billon’s key word.

The swiftness to react enables us to closely follow each fashion trend. It also ensures the means to retain our customers’ production circuits in order to offer the consumers the finished products they are expecting. Each of our customers’ requests is carefully considered and treated in the shortest possible time.

The production cycle is immediate.

Flexibility

From the 50 sample piece to the bulk production (150 m / color min.) the whole team is here to listen to your needs.

Please contact us for more information.

Quality

All our products are Oeko-Tex Standard 100 certified

Iso 9001 2015 version certified

"French innovation and know-how at the service of customers"

A 100% french production

From the yarns’ purchase up to our finished fabrics, each development’s step is done in our units to guarantee a 100% local and french production.

The human being at the heart of our company

A unified team which carries out all of the company’s values and proud of their french know-how to answer all the customers’ needs.

Innovation and cutting-edge technology

To come up with the best solution to our customers’ challenges, we own a vast machine range always at the cutting edge of technology (circular knitting machines, stripes, electronic jacquards, ribs, flat knitting machines, Rachels, etc.)